How ceramic tile is made material, manufacture, .

kilns, are used for firing tile. Wall tile, or tile that is prepared by dry grinding instead of wet milling (see #2 and #3 above), usually requires a two ...

WhatsApp)

WhatsApp) WhatsApp)

WhatsApp)

kilns, are used for firing tile. Wall tile, or tile that is prepared by dry grinding instead of wet milling (see #2 and #3 above), usually requires a two ...

cement factories, air pollution and consequences 1 cement factories, air pollution and consequences syed sana mehraj and dr. bhat

Login Required A full subscription to International Cement Review Magazine is required to view videos. If a clip is available it will play below, otherwise please ...

Earle''s Wilmington cement plant: Hull, Yorkshire ... This article is based on a document in the G T Earles archive held by the Hull History Centre catalogue ...

JK Lakshmi Cement is one of the pioneers of the cement industry and rated as one of the best cement companies in India, known for its highest quality standards in its ...

A cement is a binder, a substance used in construction that sets, hardens and adheres to other materials, binding them together. Cement is seldom used solely, but is ...

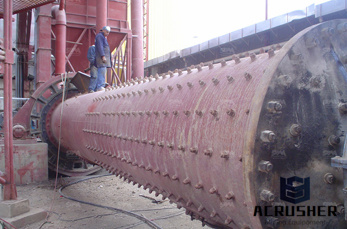

Manufacturing the cement kiln. Most Portland cement is made in a rotary kiln. Basically, this is a long cylinder rotating about its axis once every minute or two.

Reducing greenhouse gasses emissions by fostering the deployment of alternative raw materials and energy sources in the cleaner cement manufacturing process

Burning in a kiln – formation of cement clinker. The next step in the process is to heat the blended mixture of raw ingredients (the raw mix) to convert it ...

Explore Nano Concrete with Free Download of Seminar Report and PPT in PDF and DOC Format. Also Explore the Seminar Topics Paper on Nano Concrete with Abstract or ...

Portland cement is one of the most widely used materials in construction. Applications include concrete floors, walls, and pavement; concrete blocks ...

The cement industry has already reduced its emissions and will continue to do so through conventional resource and energy efficiency measures in the future.

Excellence breeds Confidence. Quantachrome Instruments represents a unique blend of design and manufacturing excellence (ISO 9001:2000 certified) with scientific and ...

Cement is a binding agent and is a key ingredient of the most used manmade material: concrete. The demand for cement is strongly correlated to the rate of economic ...

Its Variable Speed allows the operator the flexibility to move from high speed rough grinding to UKAM Industrial Superhard Tools Division of LEL Diamond Tools ...

The leading website dedicated to feed mill machinery and equipment, Since 2003. Comprehensive news, articles, information, feed machinery ...

Top manufacturer of cement packing machines, fly ash packaging machines, automatic packaging machines, bag filling machines, screw feeder other packaging ...

PT Numada is a consulting company based in Jakarta, Indonesia, established as a foreign investment company (PMA) under approval and licensing of the Indonesian ...

How does Manufacturing Technology work? Learn about assembly lines, factory production, welding all about how all the little pieces are put together to make and ...

Safal Niveshak analyses the Indian Cement industry in detail, covering the industry''s evolution, its structure, and competitive rivalry.

The company embarked on a backward integration project by putting up an 800 TPD Clinkerisation and Cement grinding unit at Patratu

List of cement companies in India, incl. top Indian cement manufacturers, along with their profile, contact details other key information Presented by Govt. Trust ...

The first step in making concrete is to prepare the cement. One type of cement, Pordand cement, is considered superior to natural cement because ...

However, at this time, even heavy industrial construction was still dominated by brick masonry, and earlier types of cement were already wellestablished in this market.

WhatsApp)

WhatsApp)